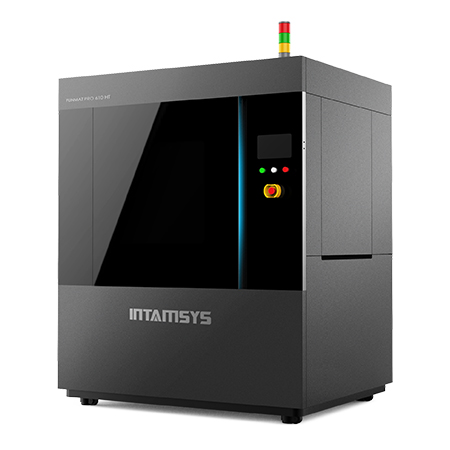

The FUNMAT PRO 610 HT is the latest machine that is part of the FUNMAT range from Chinese manufacturer INTAMSYS. It is a high-end industrial machine designed for functional parts that meet critical requirements and small series production. The largest in the range, its generous printing volume of 610 x 508 x 508 x 508 mm allows you to print large parts or multiple small parts for low volume production runs. The printer also is, according to INTAMSYS, the most feature-packed of all its machines.

As a world-leading high-tech company providing 3D printing and industrial direct additive manufacturing solutions for high-performance materials, INTAMSYS has optimized this large-format industrial FFF printer to be used in industries such as aerospace, aviation, automotive, electronic manufacturing, consumer goods, healthcare, scientific research and more. INTAMSYS also notes that the FUNMAT PRO 610 HT can be used for a vast array of applications including, but not limited to functional test prototyping, tooling and fixture manufacturing and of course direct mass production of final products, covering equipment, software, high performance materials and printing materials.

FUNMAT PRO 610 HT: Printing Precise, High-Performance Parts

The thermal system of the FUNMAT PRO 610 HT will allow you to print more technical filaments such as PEEK, PEI, PPSU, etc. Its heated chamber reaches a constant temperature of 300°C while its plateau also rises to 300°C. Its all-metal extruder has a maximum temperature of 500°C. This temperatures are ideal for printing with high-performance materials and the printer can also support almost every high-performance thermoplastic material on the market including PEEK, PEKK, PAEK, ULTEM™, PPSU, PC, PA, ASA, ABS. Indeed, these temperature help to reduce the possibility of part warpage and ensuring consistent and quality parts.

The FUNMAT PRO 610 HT has a double extrusion system that will allow you to print solid and durable functional parts. Thanks to automatic filament reloading, users will also be able to be more efficient when printing among other user-friendly features. Additionally, INTAMSYS estimates that thanks to their open material platform, users will be able to save up to 50% of costs.