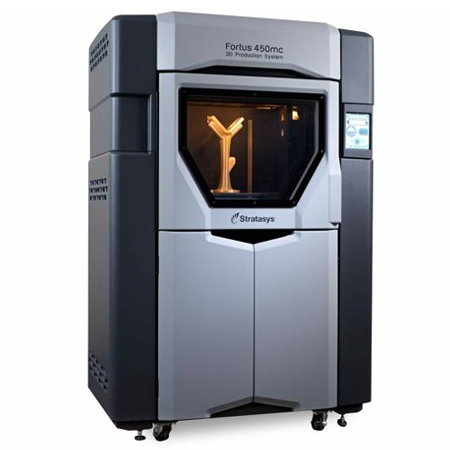

The American giant Stratasys has developed the Fortus 450mc to allow manufacturers to print large high-performance materials. Its printing volume is indeed quite generous, 406 x 355 x 406 mm. It is an ideal machine for all specialized sectors such as automotive, medical or aeronautics that will be able to create solid components, resistant prototypes and production tools of all kinds.

Fortus 450mc Features

Whether you need accurate prototypes, solid manufacturing accessories or final parts on demand, the Fortus 450mc? can be tailored to your application. It provides the materials you need for demanding production applications in any industry. From soft-jaw tooling to ESD-compatible space components, the Fortus 450mc is the multi-tool for additive manufacturing. According to the manufacturer, the Fortus 450mc is the ideal on-demand solution for cost-effective manufacturing of low-volume and production transition parts. Tool-less 3D printing allows parts to be produced much faster and at lower cost, bypassing the traditional supply chain.

In addition, the Fortus 450mc avoids the high costs and delays of traditional prototyping. Product development can be accelerated with 3D printed functional prototypes made from durable polymers. Carbon fiber, polycarbonate, PEI and PEKK are some of the most robust materials available for rapid prototyping to validate your design.

Automatic repair of broken files

The Stratasys Fortus 450mc can work with several formats, including STL, VRML and other CAD file formats such as Creo, Solidworks, NX, CATIA and Inventor. In addition, if there is a defect in a file, the 3D printer has the option to repair it directly. Finally, the connection to the machine can be easily established via WIFI or Ethernet.

Are you looking for specific requirements for the material to be printed? Do you need high temperature resistance (up to 213°C) and/ or chemical resistance? Do you need certified materials for, for example, passenger transport? Then the Fortus 450mc from Stratasys will surely be the right machine for you. This model can be individually adapted to the customer’s wishes.