Considered by many to be one of the main leaders in the additive manufacturing industry, Formlabs is regularly in the news. Marketing a wide range of resins and machines, the majority of which are aimed at the dental field, the company wants to make digital manufacturing accessible to everyone and for any type of project. Among the 5 3D printers currently offered by Formlabs, you can find the Form 3+, an SLA machine geared towards professionals.

Features of the Form 3+

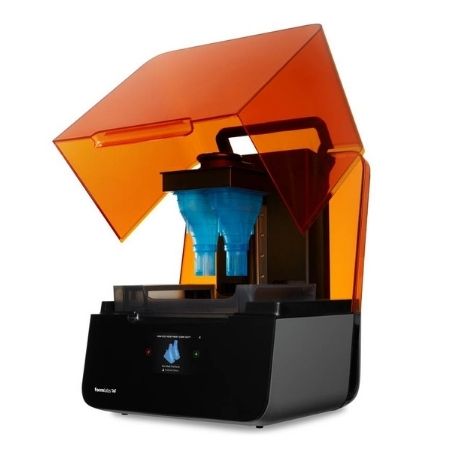

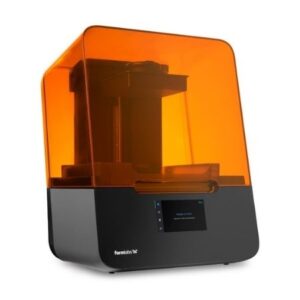

An improved version of the Form 3, the Form 3+ printer uses Formlabs’ own Low Force Stereolithography printing technology which offers quality parts with an excellent surface finish. With a print volume of 145 x 145 x 185 mm, the printer can have a part layer thickness of 300 to 25 microns. Easy to install and maintain, the machine is primarily aimed at professionals and, according to the manufacturer, can produce high quality functional prototypes and final parts in record time. Compatible with almost all Formlabs resins, the Form 3+ offers the possibility to produce many professional applications quickly. In addition, with the PreForm software it is possible to prepare models with a few clicks, to start a print remotely and to monitor its progress with the Dashboard.

For the post-treatment of resin parts, Formlabs offers Form Wash and Form Cure, two stations for cleaning and curing the parts to obtain the best mechanical properties and beautiful finishes. Regarding the maintenance of the machine, many parts are replaceable by the user in case of rare technical problems (resin tank, rollers, optical window…).