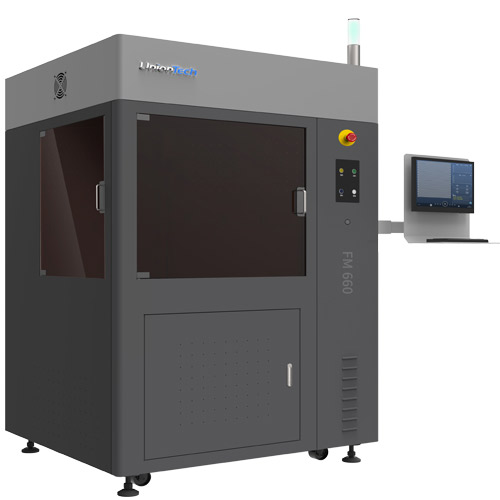

Based in China, UnionTech is a long-standing player in additive manufacturing, particularly when it comes to resin 3D printing. The manufacturer has created a wide range of SLA, DLP and LCD machines, all designed to meet the demanding needs of industry. The range includes a series dedicated to the footwear sector, such as the FM700 and FM660, whose main differences are printing volume, laser and size.

Features of the FM660 3D Printer

The FM660 uses the stereolithography 3D printing process, which consists in hardening liquid resin with a laser: layer by layer, the heat source photopolymerizes the material until the final part is obtained. Furthermore, this particular 3D printer offers a printing volume of 600 x 400 x 400 mm, which is quite large for a resin machine. Indeed, vat photopolymerization solutions often are only capable of creating smaller parts due to the limitations of the technology.

To make each part, SLA FM660 3D printer is equipped with a 365 nm laser and variable dot technology, enabling it to achieve very high levels of speed and efficiency. It’s a highly accurate solution, capable of achieving detail down to 0.06 mm. It features a remote control platform and real-time monitoring system to guarantee the desired print results. The FM660 industrial machine is particularly well-suited to the footwear industry, whether for testing new products, producing rapid tooling or mass-producing molds.