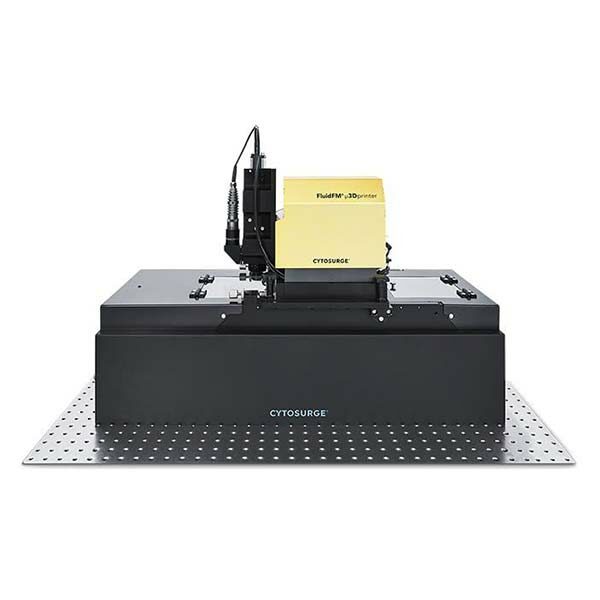

Based on the patented FluidFM technology, the FluidFM µ3Dprinter is a 3D printer that creates complex metal parts with micron-level resolution. It was developed by Swiss manufacturer CytoSurge – who you can find in interview HERE. Its purpose is to design a multitude of nanotechnology applications, whether for the cell biology sector, for example, but also for life science more broadly.

Features of the FluidFM µ3Dprinter

This professional 3D printer can create metal parts at the micrometer and submicrometer scale, whether with copper, silver or aluminum. It is easy to use and ready to use: it includes a camera and a control screen to facilitate the printing process and allow the user to monitor the printing process. The 3D printer can print parts up to 100 x 70 x 60 mm. In addition, it offers a print thickness of 0.05 mm and an XY precision of 0.25 mm. The machine is equipped with the FluidFM CAPA software. It allows to model the 3D parts quickly and efficiently. The core element of the FluidFM technology is a movable micro-pipette mounted on a leaf spring that can be positioned extremely precisely. Unlike traditional pipettes, the FluidFM technology will measure and control the forces that the pipette exerts on a surface. This pipette will deliver the liquid, filled with metal ions, necessary to manufacture the metal part.