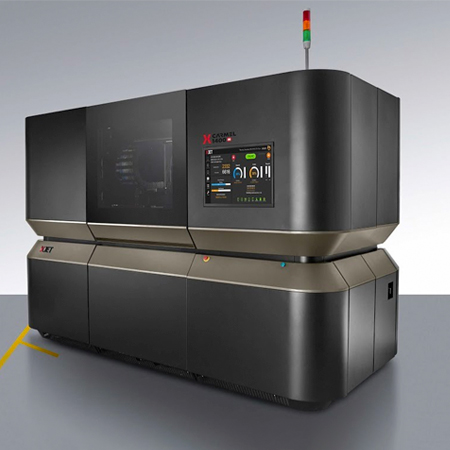

The Carmel 1400M is an industrial 3D printer developed by Israeli company XJet. Based on NanoParticle Jetting™ (NPJ) technology, it enables additive manufacturing of metal parts with high levels of detail, finish and precision.

Carmel 1400M features

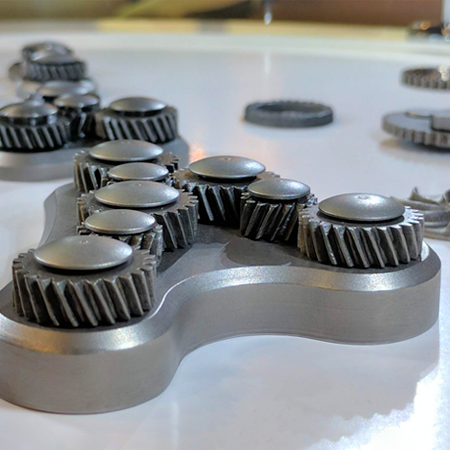

XJet’s patented 3D printing method is part of a family of technologies based on material jetting. Specifically, it uses liquid inks containing dispersed solid metal nanoparticles, which are deposited on the printing plate to produce the part layer by layer. This high-quality technology is capable of creating highly detailed, finished and precise parts, without compromising throughput or manufacturing time.

In terms of applications, the Carmel 1400M is suitable for a wide range of industries. With a maximum print volume of 500 x 140 x 200 mm, this industrial 3D printer enables simultaneous production of metal parts. The soluble material support structures dissolve easily and avoid manual labor, reducing the need for time-consuming and costly post-processing. This professional solution offers great advantages in industry, enabling manufacturers to produce metal parts with a geometric design that has never been possible before.