of the printer,Founded in 2014, Berlin-based manufacturer BigRep offers comprehensive solutions for additive manufacturing. Their product lineup includes 3D printers, software, and filaments, making them a one-stop destination for customers. Among their 3D printers are the BigRep STUDIO G2, BigRep ONE V4, and BigRep PRO.2, all utilizing FDM technology and specifically designed for industrial applications. BigRep has established a global presence with offices in Boston and Singapore.

The BigRep STUDIO G2 is tailored for industrial processing of abrasive materials, accommodating ABS, TPU, and ASA, among others. Its steel nozzle ensures durability during printing. Users have the flexibility to choose between the manufacturer’s filaments or those supplied by third-party providers with a diameter of 2.85 mm. Notably, the printer features a heated filament chamber capable of reaching temperatures up to 60 °C, ensuring optimal material storage and usage.

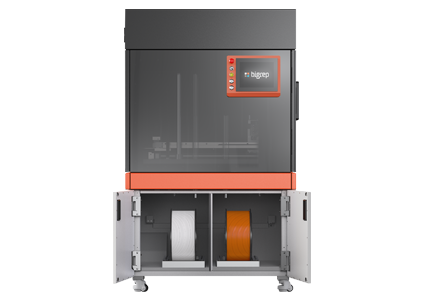

Features of the BigRep STUDIO G2 3D printer

With compact dimensions of 1715 x 1170 x 1765 mm and a weight of approximately 550 kg, the BigRep STUDIO G2 is a versatile 3D printer suitable for various environments, including office spaces. Despite its smaller size, it is capable of producing large parts with impressive quality. The printer offers a maximum print speed of 100 mm/s and can manufacture parts measuring up to 1000 x 500 x 500 mm.

Equipped with a dual extruder, the BigRep STUDIO G2 allows for increased versatility in printing. The extruder temperature can reach a maximum of 280 °C, enabling the use of a wide range of materials. The print bed’s polyimide surface can be heated to 100 °C, and it reaches a temperature of 80 °C in just 15 minutes, ensuring optimal adhesion during the printing process.

A feature of the printer, the printer’s closed pressure chamber is equipped with a BOFA air filter system, which guarantees a safe working environment, particularly when handling potentially toxic materials. Additionally, the printing process can be monitored through the built-in camera, providing real-time feedback and control. To ensure uninterrupted production, the printer notifies the user when the filament runs out, allowing for smooth operation and preventing any potential disruptions.