BigRep, headquartered in Berlin, is a leading provider of additive manufacturing solutions, offering a comprehensive range of products including 3D printers, software, and filaments. Since its establishment in 2014, BigRep has expanded its global presence with offices in Boston and Singapore. Their product lineup comprises three printers: BigRep STUDIO G2, BigRep ONE.4, and BigRep PRO.2. These machines are specifically designed for industrial environments, utilizing FDM/FFF technology to ensure exceptional print quality.

The standout feature of the BigRep ONE.4 printer is its remarkable efficiency in producing large-format prints. This capability makes it well-suited for a variety of applications such as architecture, prototyping, and research. While it supports a slightly narrower range of materials compared to other BigRep models, the ONE.4 is still capable of handling PLA, TPU, PETG, and other compatible materials. Additionally, users have the flexibility to choose between manufacturer-supplied or third-party filaments for their printer, granting them greater freedom and customization options based on their specific requirements.

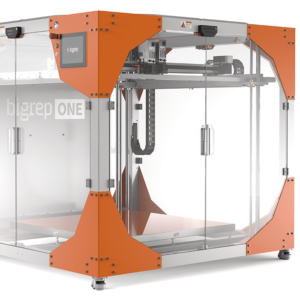

Features of the BigRep ONE.4

The BigRep ONE.4 boasts dimensions of 1850 x 2250 x 1725 mm and weighs 460 kg, providing a sturdy and robust build. It has the capability to produce parts with a maximum size of one cubic meter, delivering efficient printing speeds of up to 500 mm/s. The print bed is equipped with heating functionality and can reach a maximum temperature of 80 °C. The polyimide coating on the print bed ensures excellent adhesion during the printing process, as affirmed by BigRep. Additionally, the printer incorporates an integrated sensor for efficient leveling procedures. Users have the flexibility to select between single, double, or twin mode extruders, catering to their specific needs.

Furthermore, the BigRep ONE.4 offers a user-friendly experience through its intuitive touch screen interface, guaranteeing ease of use. Notable features of this 3D printer include a built-in camera for monitoring the printing process and the ability to resume printing in the event of a power failure, ensuring uninterrupted workflows and preventing material waste.