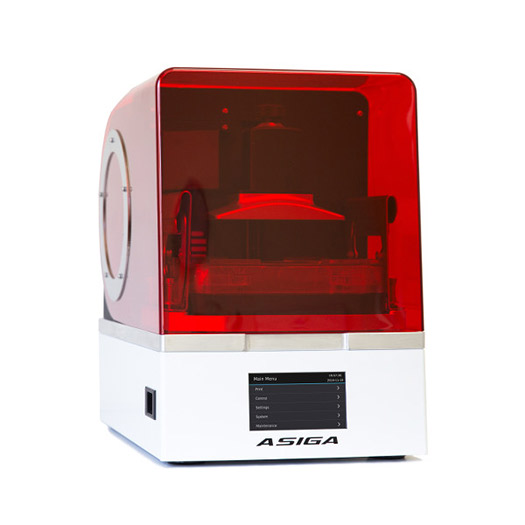

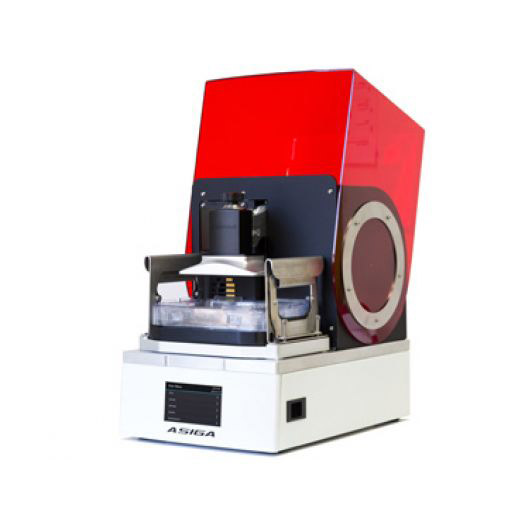

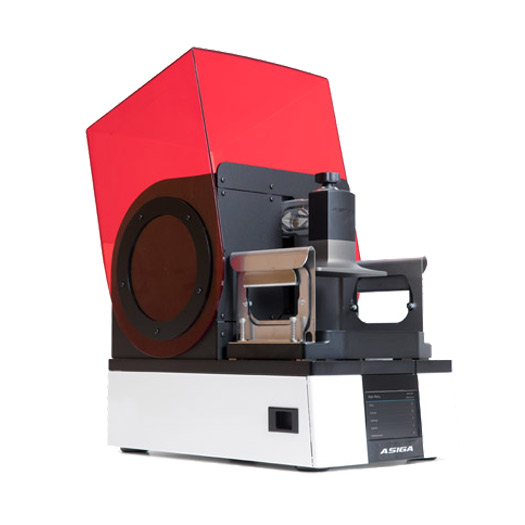

The manufacturer Asiga specializes in the development of resin 3D printers, especially for the dental sector. Since 2011, the company has developed a range of devices that are easy to use and relatively affordable. All of its 3D printers are now manufactured in Australia, but the company also has offices in the U.S. and Germany. Its range of solutions includes the MAX 3D printer, the most compact and affordable printer.

The Features of the MAX 3D printer

The machine is based on the light curing process and in particular on DLP technology. It is available with different types of LEDs – 365 nm, 385 nm or 405 nm – to allow more or less accurate curing of the resin layers, depending on the desired application. The MAX 3D printer, with a print volume of 119 x 67 x 75 mm, features an internal radiometer that automatically adjusts the duration of light curing to ensure high detail and optimal quality.

In terms of materials, the MAX 3D printer is an open device, which means it is compatible with over 500 resins available on the market. Depending on your application – dentistry, jewelry, industry, etc. – you choose the best option for your requirements. For example, the 3D printer is compatible with resins developed by BASF, Henkel, Graphy, Evonik or NexaDent.

The instrument currently comes with a calibration kit, a 1 kg bottle of resin of your choice, the manufacturer’s Composer software and unlimited technical support.

Applications of the Machine

The MAX 3D printer is particularly suited to the medical field and ideal for designing custom medical devices, whether for dentistry or audiology. One dental lab, Cosmodent, reports, “My path to 3D printing was a real roller coaster ride until I found Asiga. My Asiga 3D printers provide the most reliable and accurate results compared to any other equipment in my lab. If you’re looking for perfect 3D prints day after day, you won’t find a better investment.”