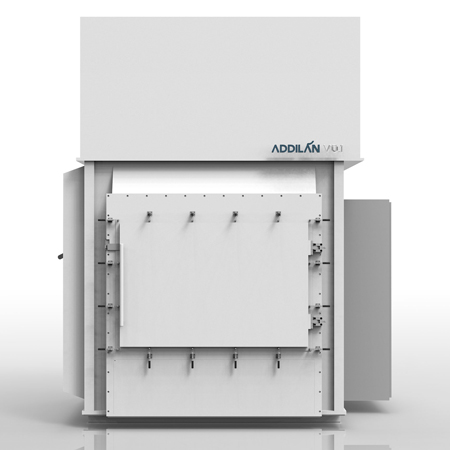

Based in Vizcaya, Addilan is a Basque company dedicated to metal additive manufacturing. Its machines uses WAAM 3D printing technology, a derivative of Directed Energy Deposition, and are designed to offer a competitive alternative to medium to large-scale component manufacturers. The Spanish manufacturer’s two Arclan solutions, the P1200-4x and the 1000-5X feature a closed and inert chamber with a special loading and unloading system to ensure part quality during the manufacturing process. Let’s take a look at the properties of the Arclan P1200-4X 3D printer.

Features of the Arclan P1200-4X

This machine uses metal wire as the raw material and welding as the heat source to fuse the layers. WAAM technology meets the needs of the entire industrial sector that manufactures large parts. In addition to being a scalable machine up to 5 meters, the Arclan P1200-4X has hybrid manufacturing, meaning it incorporates a CNC manufacturing module for surface finishing of additive parts. In terms of materials, the 3D printer can work with steel, titanium alloys, super alloys and aluminum alloys. As for other features of the Addilan machine, the 3D printer is equipped with a heated platen and a touch screen. The 3D printing solution also benefits from the automatic calibration system.