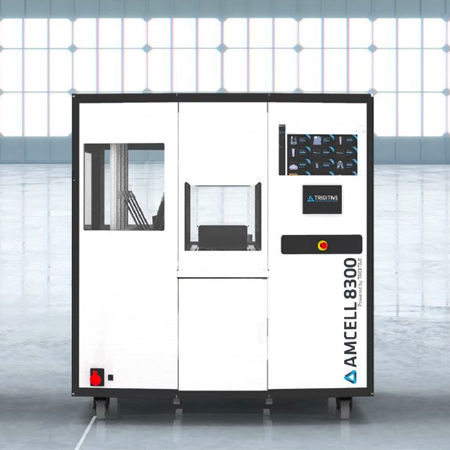

Triditive is a young company located in Asturias, northern Spain, that quickly gained recognition in the industry with the launch of the AMCELL system in 2018. This machine is an automated additive manufacturing solution that allows for the mass production of end-use parts, using polymers and metals. One of the two machines launched by the Spanish manufacturer is the AMCELL 8300® solution, though the AMCELL 1400® 3D printer is also in their collection

Features of the AMCELL 8300® 3D Printer

With the ability to create parts with thermoplastics, reinforced polyamides and metals (such as stainless steel), this system uses a propriety tecnology, known as AMD (Automated Material Deposition) extrusion. The high-performance industrial 3D printer can produce parts up to a size of 300 x 300 x 350 mm. As for the physical dimensions of the Triditive 3D printer, it measures 3400 x 2000 x 2000 for a weight of 1300 kg. The machine is equipped with a nozzle with a diameter of 0.4 to 0.8 mm and a minimum layer height of 30 μm. In terms of the materials compatible with the AMCELL 8300® 3D printer, you can find:

- Polymers: ABS, ASA, CPE, HIPS, IGLIDUR I150-PF. PA, PC, PETG, PLA, TPU, Vinyl.

- Composites : PA+Aramid, PA+CF, PC+ABS, PC+PBT.

- Metals: SS316L, SS17-4PH, Inconel, Titanium.

In addition, the AMCELL 8300® 3D printer includes EVAM software, a cloud-based solution that takes care of production control and management. With its continuous functionality, the Triditive system requires minimal human intervention. In short, the company aspires to take additive manufacturing from the prototyping phase to the mass production of end-use parts.