Samylabs’ newest solution, the ALBA 300 3D printer, is designed to work in both industrial and office environments. A compact 3D printer that uses SLM (selective laser melting) technology, the machine is equipped with a 300W laser as well as a closed chamber, allowing for printing in argon and nitrogen, helping to keep a better environment for metal 3D printing. The 3D printer is capable of designing parts from stainless steels and various alloys such as Inconel and chrome-cobalt.

The entire 3D printing process was developed by Samylabs and ONA, from the software and the control of the laser system, to the final mechanical and electrical details. The lamination software, which is fully integrated into the printer, simplifies the printing process and allows for real-time control of key control parameters, as well as changes in density and energy distribution.

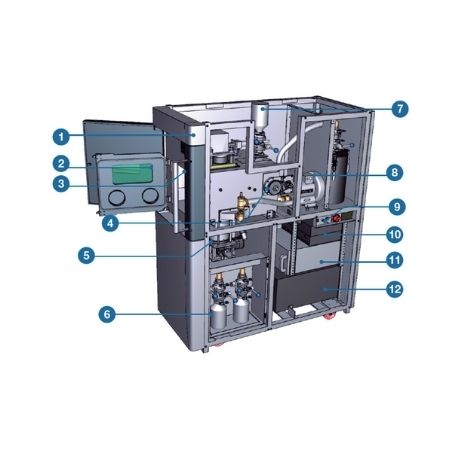

Features of the ALBA 300 3D Printer

With a stainless steel interior and a simple, elegant aesthetic design, the machine has been designed to be easy to use. For example, the large front door can be removed to make the operator’s job easier. The manufacturer says the ALBA 300 produces parts with a high quality finish, but its main advantage is ease of use and cleaning.