Aconity3D GmbH is a German manufacturer of metal 3D printers, based in Aachen, the birthplace of laser powder bed fusion (LPBF) technology. The company focuses on modular machines that are suitable for a wide range of new industrial applications for metal 3D printing, from medicine to automotive, energy and aerospace.

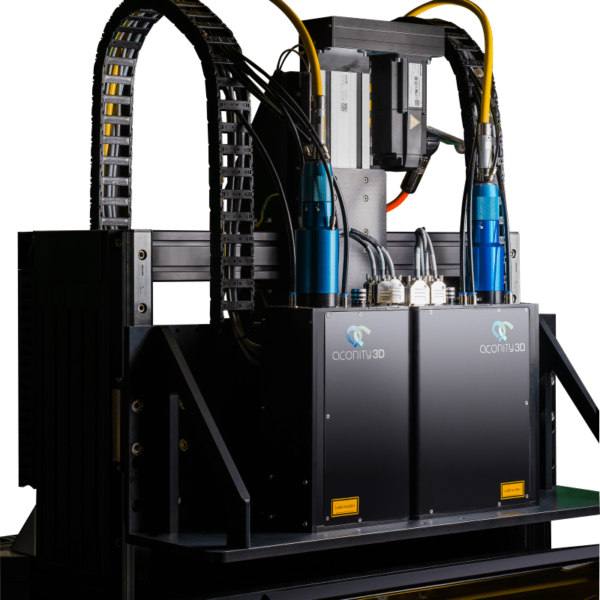

The AconityMIDI+ is Aconity3D’s latest machine concept for efficient LPBF industrial applications. The interchangeable processing chamber allows parallel set-up times and therefore reduced part costs. For maximum industrial flexibility and quality assurance, it incorporates a high-temperature preheating up to 1,000 °C and a completely new monitoring system. The AconityMIDI+ can be equipped with up to 4 lasers in the QUATTRO laser configuration, further increasing productivity. Like all Aconity systems, the AconityMIDI+ is equipped with the web-based control software AconitySTUDIO, which allows remote access to all relevant process parameters and machine components.

Furthermore, the AconityMIDI+ is available with a revolutionary multi-material powder coating system that enables the production of dual metal parts. As high flexibility is the key to exploring countless different applications in additive manufacturing, the AconityMIDI+ can be equipped with additional options such as:

- High temperature preheating (up to 1,000 °C) for a considerably expanded range of applicable materials, such as titanium aluminides and some nickel-based superalloys,

- The Dual-Metal Recoater module, which for the first time allows the production of multi-material metal parts using L-PBF technology,

- An additional, fully interchangeable processing chamber with adjustment station, which allows a complete parallelisation of the set-up times and thus cost-effective production,

- Process monitoring options using high-speed imaging and pyrometry to improve the quality of parts for critical applications using certified process pathways

- Up to 4 lasers in the QUATTRO laser configuration with full overlap of the construction plate Ø 250 mm for increased productivity,

- The “master/slave” configuration of several laser beams to exploit post- or preheating during production.

The AconitySTUDIO software suite offers complete freedom and autonomy in terms of process parameters and applied materials for an emerging and growing field of applications. Prospective customers can configure their individual system for any specific application using Aconity3D’s new online machine configurator.